Product description

Mgo c brick is made from fused magnesia, high-purity magnesia and graphite, and are formed by high pressure molding and low temperature treatment. Different grades of mgo c brick can be selected according to different smelting conditions , service life in heats and smelting steel grades.

Advantages of CH Refractories:

CH refractories will provide free design of mgo c brick lining for your ladle, (EAF) electric arc furnace refractory lining and blast furnace refractory, according to your furnace working condition and heats requirement,refining time to guarantee service life.

mgo c brick manufactured by CH Refractories has many excellent mechanical properties such as high strength, high toughness and high hardness. In harsh environments such as high temperature and high pressure, magnesium-carbon bricks can maintain the integrity and strength of the structure and effectively resist external pressure and impact.

Application of mgo c brick:

mgo c brick is widely used in steel, aluminum electrolysis, petrochemical and other industries, because they have excellent high temperature, corrosion resistance, wear resistance, high strength and electrical conductivity characteristics.

Physical and chemical index

|

Brands |

MT-12A |

MT-12B |

MT-12C |

MT-14A |

MT-14B |

MT-14C |

|

MgO/%≥ |

78 |

76 |

74 |

76 |

74 |

72 |

|

C/%≥ |

12 |

12 |

12 |

14 |

14 |

14 |

|

Apparent porosity/% ≤ |

4 |

5 |

6 |

4 |

5 |

6 |

|

Bulk density g/cm3 ≥ |

2.98 |

2.96 |

2.98 |

2.98 |

2.96 |

2.95 |

|

Crushing strength/Mpa ≥ |

40 |

40 |

40 |

40 |

40 |

35 |

|

Hot modulus of rupture(1450℃)/Mpa |

8 |

7 |

6 |

12 |

10 |

8 |

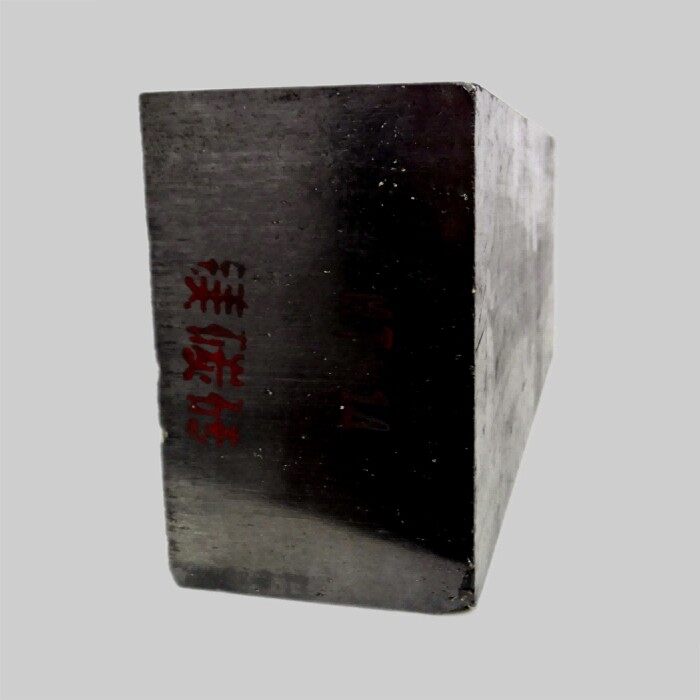

Packages:

Physical and chemical index

|

Brands |

MT-12A |

MT-12B |

MT-12C |

MT-14A |

MT-14B |

MT-14C |

|

MgO/%≥ |

78 |

76 |

74 |

76 |

74 |

72 |

|

C/%≥ |

12 |

12 |

12 |

14 |

14 |

14 |

|

Apparent porosity/% ≤ |

4 |

5 |

6 |

4 |

5 |

6 |

|

Bulk density g/cm3 ≥ |

2.98 |

2.96 |

2.98 |

2.98 |

2.96 |

2.95 |

|

Crushing strength/Mpa ≥ |

40 |

40 |

40 |

40 |

40 |

35 |

|

Hot modulus of rupture(1450℃)/Mpa |

8 |

7 |

6 |

12 |

10 |

8 |