Product description

Portland bonded castable refractory forge are made of ordinary Portland cement, slag Portland cement and Portland heat-resistant cement as binding materials, together with refractory aggregates and powders. Its operating temperature is 700-1200°C, and it can be used in overall load-bearing heat-resistant structures and kiln linings. It is especially used in projects such as the foundation of thermal equipment and floor flues, chimney linings, and thermal storage

The price of castables is determined based on the density and aluminum content. The price of castables produced from high-aluminum materials with low density will be relatively low. If it is a castable with high density and high aluminum content, the price will be lower. Relatively high.

Applications of castable refractory forge:

The service temperature of high-aluminum refractory castables is 1300°C. It is mainly used in the lining of various kilns such as boilers, blast furnaces, hot blast furnaces and heating furnaces.

Physical and chemical index of castable refractory forge

|

Items |

CH-75 |

CH-80 |

CH-85 |

|

|

AL2O3 /% ≥ |

75 |

80 |

85 |

|

|

Bulk density g/cm3 ≥ |

2.7 |

2.8 |

2.9 |

|

|

Flexural strength/ MPa≥ |

110℃×24h |

16 |

18 |

20 |

|

1100℃×3h |

18 |

20 |

20 |

|

|

Compressive strength /MPa≥ |

110℃×24h |

70 |

80 |

80 |

|

1100℃×3h |

90 |

100 |

100 |

|

|

Normal wear /cm3 ≤ |

8 |

8 |

8 |

|

|

Thermal shock stability TSR (900℃ ,Water cooling) /Times≥ |

20 |

20 |

20 |

|

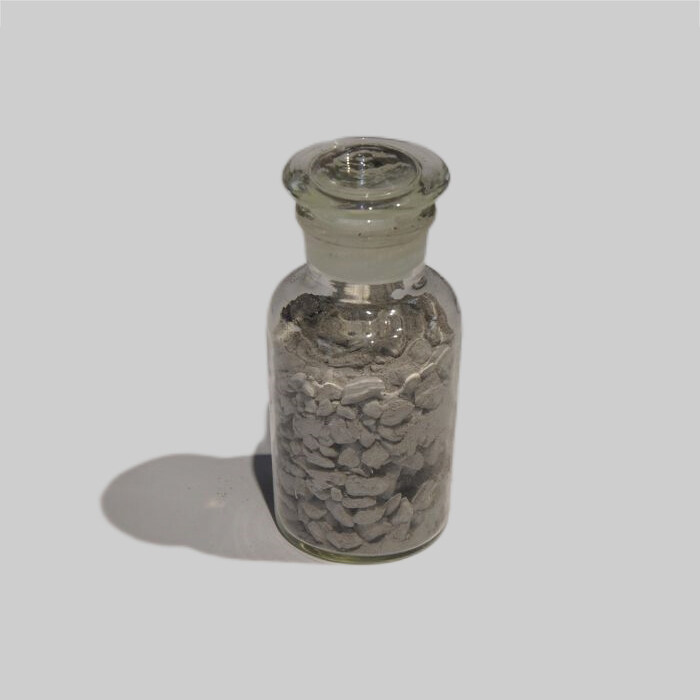

Packages

Physical and chemical index of castable refractory forge

|

Items |

CH-75 |

CH-80 |

CH-85 |

|

|

AL2O3 /% ≥ |

75 |

80 |

85 |

|

|

Bulk density g/cm3 ≥ |

2.7 |

2.8 |

2.9 |

|

|

Flexural strength/ MPa≥ |

110℃×24h |

16 |

18 |

20 |

|

1100℃×3h |

18 |

20 |

20 |

|

|

Compressive strength /MPa≥ |

110℃×24h |

70 |

80 |

80 |

|

1100℃×3h |

90 |

100 |

100 |

|

|

Normal wear /cm3 ≤ |

8 |

8 |

8 |

|

|

Thermal shock stability TSR (900℃ ,Water cooling) /Times≥ |

20 |

20 |

20 |

|