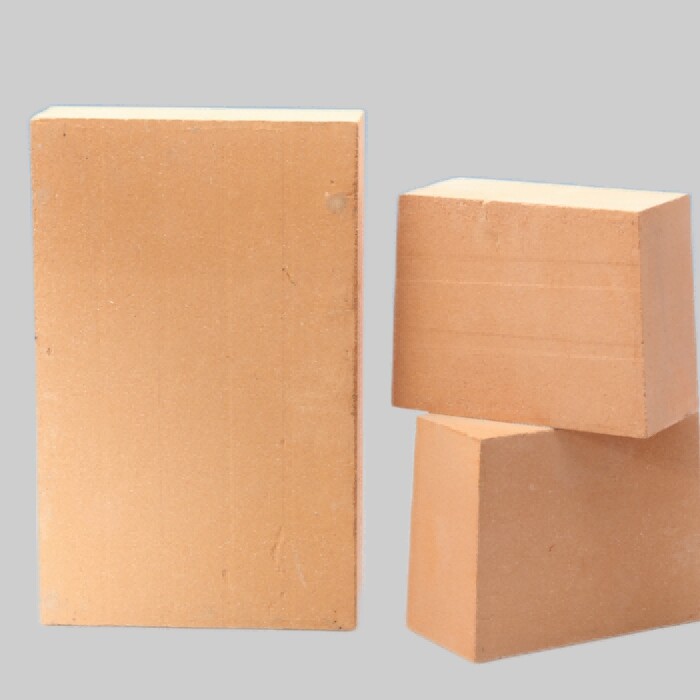

Product description

Clay lightweight insulating fire bricks: refers to the aluminum content of 30%-46% light firebrick, with clay clinker or light clinker and plastic clay as the main raw material, using combustible method production. The bulk density is 0.75-1.20g/cm3, the compressive strength is 2.0-5.9MPa, the thermal conductivity is 0.221-0.442W (m.k), the service temperature is 1200-1400℃, used for various industrial furnaces do not contact the melt and no corrosive gas action of the heat insulation layer material.

High aluminum lightweight insulating fire bricks: refers to the content of Al2O3 in more than 46% of light firebrick. The brick made of natural high alumina clinker is called ordinary light high alumina brick. Light corundum brick is made of fused alumina and its main crystal phase is corundum. Lightweight high aluminum bricks are usually produced by the foam method, with a volume density of 0.4-1.35g/cm3, a porosity of 66%-75%, a compressive strength of 1.3-8.1MPa, and a thermal conductivity of 0.291-0.582W (m.k). Ordinary light high aluminum brick using temperature of 1350-1500℃, suitable for hydrogen, CO and other gases as the protective atmosphere of the kiln. Lightweight corundum brick can be used as furnace lining with the temperature reaching 1650-1800℃, which can directly contact the flame, but it should not be eroded by slag.

Mullite lightweight insulating fire bricks: refers to the Al2O3 content of 50%-85% light firebrick, with mullite as the main crystalline phase and the combination of high quality insulation materials. The main characteristics are: high strength of high temperature structure, low creep at high temperature, small thermal expansion coefficient, strong floc resistance, excellent thermal shock resistance. According to the different aluminum content and volume density, the use of temperature of 1350-1700℃, can directly contact the flame furnace working layer lining.

Advantages of CH Refractories manufactured lightweight insulating fire bricks

Selected raw materials: Sufficient raw materials and selected quality ensure product quality.

Standardized production workshop:We have sufficient production capacity for large-volume orders and can customize various refractory products.

Fully automated production:Strict control on product quality and standardized production workshops.

Sufficient stock:The large warehouse has sufficient supply to meet your various requirments and save your time.

Physical and chemical index of lightweight firebrick

|

Brands |

JM23-0.6 |

JM23-0.8 |

JM23-1.0 |

JM26-0.6 |

JM26-0.8 |

JM26-1.0 |

JM28-1.0 |

JM28-1.2 |

|

Bulk density g/cm3 ≥ |

0.6 |

0.8 |

1.0 |

0.6 |

0.8 |

1.0 |

1.0 |

1.2 |

|

CCS/Mpa ≥ |

1.5 |

2.5 |

4.2 |

1.5 |

3.2 |

4.0 |

4.0 |

5 |

|

thermal shock resistance(1100℃)/times ≥ |

10 |

20 |

20 |

10 |

20 |

20 |

20 |

20 |

|

The reheating line changes by no more than 1% of the test temperature ℃/%≤ |

1300x12 |

1300x12 |

1300x12 |

1400x12 |

1400x12 |

1400x12 |

1500x12 |

1500x12 |

|

Thermal conductivity average temperature350±25℃(W/m.k) |

0.2 |

0.23 |

0.33 |

0.2 |

0.25 |

0.33 |

0.35 |

0.4 |

|

Al2O3%≥ |

48 |

49 |

50 |

55 |

57 |

57 |

60 |

67 |

|

Fe2O3% |

0.9 |

0.9 |

0.9 |

0.8 |

0.8 |

0.8 |

0.7 |

0.6 |

Packages and delivery:

Physical and chemical index of lightweight firebrick

|

Brands |

JM23-0.6 |

JM23-0.8 |

JM23-1.0 |

JM26-0.6 |

JM26-0.8 |

JM26-1.0 |

JM28-1.0 |

JM28-1.2 |

|

Bulk density g/cm3 ≥ |

0.6 |

0.8 |

1.0 |

0.6 |

0.8 |

1.0 |

1.0 |

1.2 |

|

CCS/Mpa ≥ |

1.5 |

2.5 |

4.2 |

1.5 |

3.2 |

4.0 |

4.0 |

5 |

|

thermal shock resistance(1100℃)/times ≥ |

10 |

20 |

20 |

10 |

20 |

20 |

20 |

20 |

|

The reheating line changes by no more than 1% of the test temperature ℃/%≤ |

1300x12 |

1300x12 |

1300x12 |

1400x12 |

1400x12 |

1400x12 |

1500x12 |

1500x12 |

|

Thermal conductivity average temperature350±25℃(W/m.k) |

0.2 |

0.23 |

0.33 |

0.2 |

0.25 |

0.33 |

0.35 |

0.4 |

|

Al2O3%≥ |

48 |

49 |

50 |

55 |

57 |

57 |

60 |

67 |

|

Fe2O3% |

0.9 |

0.9 |

0.9 |

0.8 |

0.8 |

0.8 |

0.7 |

0.6 |